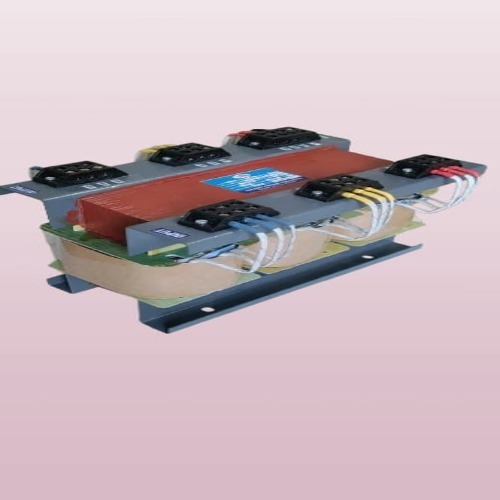

THREE PHASE STEP DOWN TRANSFORMER Specification

- Product Type

- Electrical Transformer

- Coil Number

- Autotransformer

THREE PHASE STEP DOWN TRANSFORMER Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 30 Per Month

- Main Domestic Market

- South India

About THREE PHASE STEP DOWN TRANSFORMER

THREE PHASE STEP DOWN TRANSFORMER SPECIFICATION DESCRIPTION Transformer Type A three phase step down transformer is used to reduce a higher three phase voltage on the primary side to a lower three phase voltage on the secondary side. It is commonly used in industrial, commercial, and power distribution systems. Power Rating The rating is given in kilovolt amperes or kVA. Common sizes include 5 kVA, 10 kVA, 25 kVA, 50 kVA, 100 kVA, and higher. The power rating must be selected based on the total connected load. Primary Voltage The input voltage supplied to the transformer. Typical primary voltages include 415 volts, 400 volts, 380 volts, 480 volts, or other high voltage sources depending on the region. Secondary Voltage The output voltage delivered to the load. This is lower than the primary voltage. Common secondary voltages include 220 volts, 208 volts, or 120 volts in three phase configurations. Frequency The standard operating frequency is either 50 hertz or 60 hertz. Many transformers are designed to support both. Winding Configuration The windings can be connected in delta or star configuration. Typical combinations include delta to star, delta to delta, star to delta, or star to star based on system requirements. Insulation Class Indicates the temperature tolerance of winding insulation. Class B is rated for 130 degrees Celsius, Class F for 155 degrees, and Class H for 180 degrees. Cooling Method Most three phase step down transformers are dry type and naturally air cooled. Larger units may use forced air cooling with fans. Oil cooled transformers are also used for high power ratings. Efficiency Efficiency is typically between 95 percent and 98 percent depending on design and load conditions. Mounting Type Usually floor mounted because of the size and weight. Mounting can vary based on the enclosure and site conditions. Enclosure Type Transformers may be open type for indoor protected locations or enclosed with protection ratings such as IP23 or IP54 for outdoor or industrial environments. Grounding The secondary side may include a neutral point and can be grounded depending on the application. Proper grounding ensures safety and stable operation. Applications Used to supply machinery, control panels, motor loads, and equipment that require lower voltages than the main supply voltage. Compliance and Standards Designed according to standards such as IEC 60076, IS 2026, or other applicable national or international regulations. May be UL or CE certified depending on the market.